Since entrepreneurship, through unremitting efforts to struggle, the company has a strong processing capacity and good talent, the new vision industry and trade is booming, advancing the mental outlook to meet new opportunities and challenges, and will, as always, adhere to the principle of "customer first" and "excellence" technical pursuit, on the basis of equality and mutual benefit, Establish and develop business relationship with you, to provide you with the best mold products.

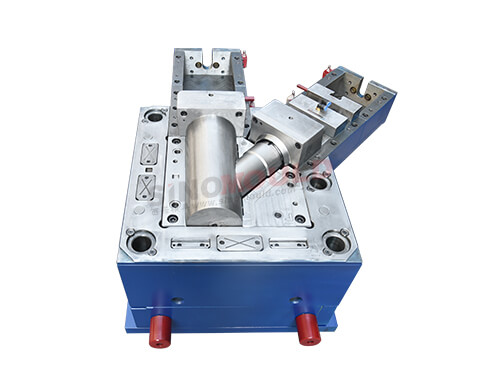

Our company has strong technical force, has the first CAD/CAM/CAE aided design CNC computer processing center, CNC engraving, CNC lathe, electric spark, wire cutting and other mold finishing complete set of equipment, product design and foot bath mold manufacturing has more than 10 years of practical experience, the company is a department, industry and trade in one of the comprehensive enterprise. It has the comprehensive ability of industrial product design, mold design and manufacture, plastic product production and complete machine. The company is a leading manufacturer of pipe fitting moulds. PVC tube mould tooling generally use Shanghai P20, Germany 2316 (if you want to mold * guaranteed quality, it is recommended to use Germany 2316 because Germany 2316 through our company's mold production process, not only can improve the life of the mold, also can increase the mold the surface glossiness of the injection molding products, at the same time there will be no flash/burrs.) PPR pipe fitting mold, PE pipe fitting mold I suggest that the core, cavity use 2738,718, die frame use 45# tempering.

Mold protection is more important than mold maintenance, the more the number of mold maintenance, the shorter its life; The better the mold is maintained, the longer its service life will be.

Injection pipe fitting moulds maintenance is mainly divided into three points :(1) production maintenance of all kinds of moving parts such as needle, row position, guide column, guide sleeve refueling, mold surface cleaning, cooling water flow, this is the mold production every day to maintain. (2) Injection mold regular maintenance: regular maintenance including daily maintenance but also exhaust groove cleaning, trapped gas burned black position exhaust, damage, wear parts correction, etc.. (3) Appearance maintenance: paint the outside of the mold embryo to avoid rust. When the mold is under the mold, the fixed and moving mold should be coated with anti-rust oil. The mold should be closed tightly when saved to prevent dust from entering the cavity.