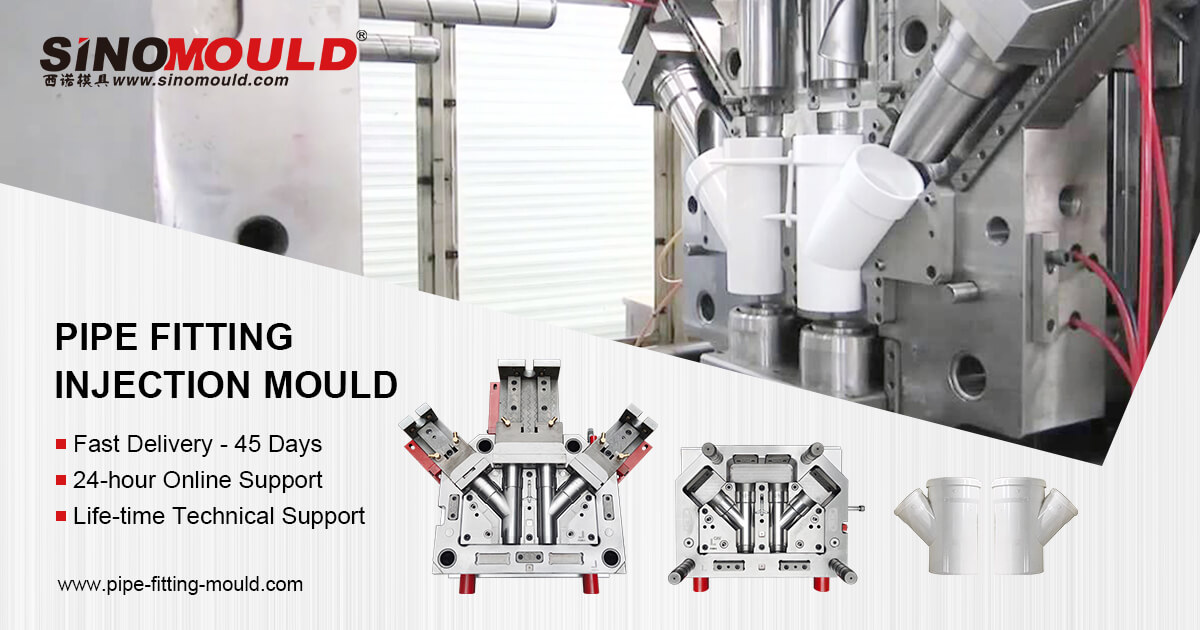

SINO MOULD produces all kinds of moulds and plastic products, and annually produces more than 1200 sets of large, medium and small moulds, including PVC/PPR pipe moulds. With precise CAD/CAM/CAE aided design CNC computer machining center, CNC fine carving, high-speed machining center, CNC lathe, edM, wire cutting and other die finishing equipment, and fully combined with the regional resource advantages, quality as the main line, constantly strengthen quality integrity management, the implementation of performance mode. People-oriented management philosophy, to attract a large number of good talents and management personnel. Established a perfect production management system and quality management system, the formation of a set of scientific, management mode, product development, market expansion. With high quality, good market service, won the trust of the market and customers.

Highlight 1: design

Traditional mold in the research and development of production using oblique guide pillar, such a design advantage is to save the mold cost, but the great disadvantage is the loss of the mold itself is too large, greatly reduce the life of the mold.

To overcome this design flaw, we use cylinders instead of bevel guides.

Benefits:

1. Ensure the stability of the mold, the quality of the mold is more than three times that of ordinary mold.

2 reduce the friction coefficient inside the mold, prolong the life of the mold

3. For the mold life is particularly high requirements, we can inlay graphite on the mold slider to play the greatest lubrication role.

Highlight 2: heat treatment of materials

In order to save the mold production process, the general mold factory processes the mold after heat treatment, so that the hardness of the mold material can not meet the expected requirements or standards. If the mold with high requirements can only use steel with high hardness, the cost will increase.

We cooperated with a foreign customer and learned a technology that can increase the hardness requirements of steel and save costs to a large extent:

After heat treatment, the steel is tempered to improve the hardness by quenching

Mold maintenance knowledge:

Mold maintenance is more important than mold maintenance, the more the number of mold maintenance, the shorter its life; The better the mold is maintained, the longer its service life will be.

Notes for mold maintenance

A.For the moving parts, refueling is necessary for daily maintenance;

B.the die surface must be clean: no label paper shall be stuck on the P/L surface. The goods continue to be carded before the die is taken out, and the P/L bit glue wire is serious;

C.If any abnormality is found, it must be repaired in time if there is a big sound of opening and closing molds.