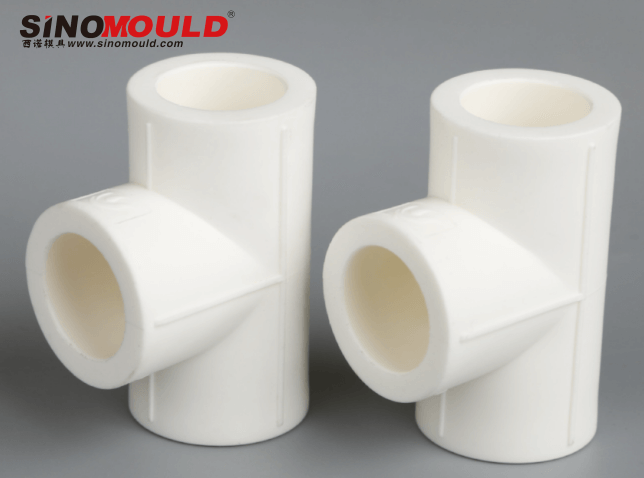

1.Improve the cooling conditions during grinding, such as the use of oil sand wheel or internal cooling grinding wheel and other measures. By introducing the cutting fluid into the center of grinding wheel, the cutting fluid can directly enter the grinding zone to play an effective cooling role and prevent the workpiece surface from being burned. Rational use of cooling lubrication fluid, cooling, washing, lubrication of the three major roles, to keep the cooling lubrication clean, so as to control the grinding heat within the allowable range, to prevent the thermal deformation of xINO plastic pipe parts die.

2.The quenching stress after heat treatment is reduced to the minimum, because the quenching stress, network carbonization structure under the action of grinding force, the structure of phase transformation is easy to crack the workpiece. In order to eliminate the residual stress of high precision die grinding, low temperature aging treatment should be carried out after grinding to improve toughness.

3.Eliminate grinding stress can also be the mold in 260 ~ 315℃ salt bath soak 1.5min, and then in 30℃ oil cooling, so that the hardness can be reduced by 1HRC, residual stress reduced by 40% ~ 65%.

4.Attention should be paid to the influence of ambient temperature and constant temperature grinding is required for precision grinding of plastic pipe fitting moulds with size tolerance within 0.01mm. According to the calculation, when the temperature difference is 3℃, the material changes about 10.8μm (10.8=1.2×3×3, the deformation per 100mm is 1.2μm/℃), and the influence of this factor should be fully considered in all finishing processes.

5.An exhaust port shall be opened at the bottom of the guide sleeve.Do not install positioning pins without gaps.And

there should be no iron filings in the oil way holes on the mold base.This is important in the plastic pipe fitting process point.