SINO MOULD has a set of mold design, research and development, production, sales, service professional team, at the same time has a series of equipment from mold design and manufacturing to testing and debugging, to achieve the overall cooperation from 3d modeling design to machining center. The products are highly praised by customers at home and abroad for their novel appearance, high quality and low price.

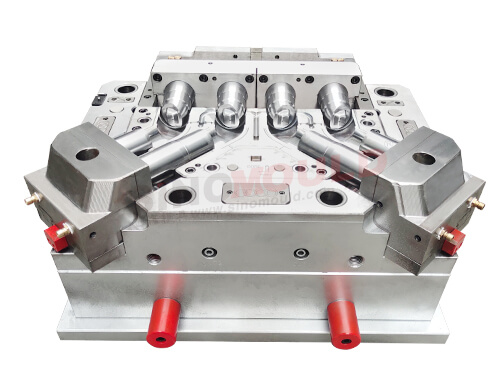

PPR pipe fitting mold is a kind of mold that is often used in the production of plastic pipes. Because of its characteristics of convenient processing, it is widely used in PPR production enterprises everywhere. In terms of production and use requirements, PPR mould has strict production requirements.

1: high accuracy

The precision value of PPR mold is related to its production precision when the product is used in the later stage, so the production of PPR mold is completed on a variety of equipment with high precision. The production error of PPR mold is within a few microns, and precision is a basic requirement of PPR mold.

2: high strength

PPR mold in the use of the process, often need to continue to use. Before processing PPR mold, the relevant production materials need to be processed by thermal processing, in order to ensure that the material itself has a certain hardness and strength, otherwise when used, the size and mold deformation, the quality of product production can not be guaranteed.

3: antioxidant

The use of PPR mold, there is no specific environmental requirements, in a variety of different environments, PPR mold is required to have a certain oxidation resistance, after the electrical treatment, the need for oxidation prevention treatment, so as to improve the use time.

4: easy disassembly and assembly

In the use of PPR mold, when there are all kinds of residual materials, it needs to be cleaned up. The mold needs to have stable processing performance and easy disassembly, otherwise the user will face some difficulties in cleaning the mold when using it. This is a problem that needs to be considered in product design and production.