Today's logistics gradually toward the direction of service circulation, due to the highly intensive production line, plastic pipe fittings more and more attention by enterprises. The quality of plastic pipe is much higher than that of plastic pipe fittings. Be recognized by all respects, the quality nature of plastic pipe is the primary factor of the enterprise choose and buy that those prepare to use plastic pipe.

Traditional water supply pipe fitting are usually iron or copper, under the limitations of previous technology, iron, copper pipe fitting application is very common, but people still found the use of iron, copper pipe fittings weaknesses, it is a high potential safety hazard, bacteria, 2 it is iron, copper pipe material cost is high, economic and environmental protection. With the development of science and technology, plastic pipe fittings come on stage, it has the advantage of metal pipe fittings.

Plastic pipe material, in comparison with the traditional metal and cement pipe with light weight, generally only 1/6-1/10 of metal pipe, have good corrosion resistance, impact resistance and tensile strength of the plastic tube surface is larger than that of cast iron pipe is smooth, small friction coefficient, fluid resistance small, can reduce energy consumption of water by more than 5%, good comprehensive energy saving, make right 75% lower energy consumption, easy to transport, The installation is simple and the service life is as long as 30-50 years.

Comprehensive performance: good chemical corrosion resistance, long service life, good heat preservation, save heat preservation cost, smooth inner wall, no scale, no bacteria breeding, high impact strength, strong creep resistance, widely used in food, pharmaceutical, anti-corrosion and communication engineering and other industries! ABS plastic pipe can be used for decades indoors generally, such as buried in the ground or water life will be longer.

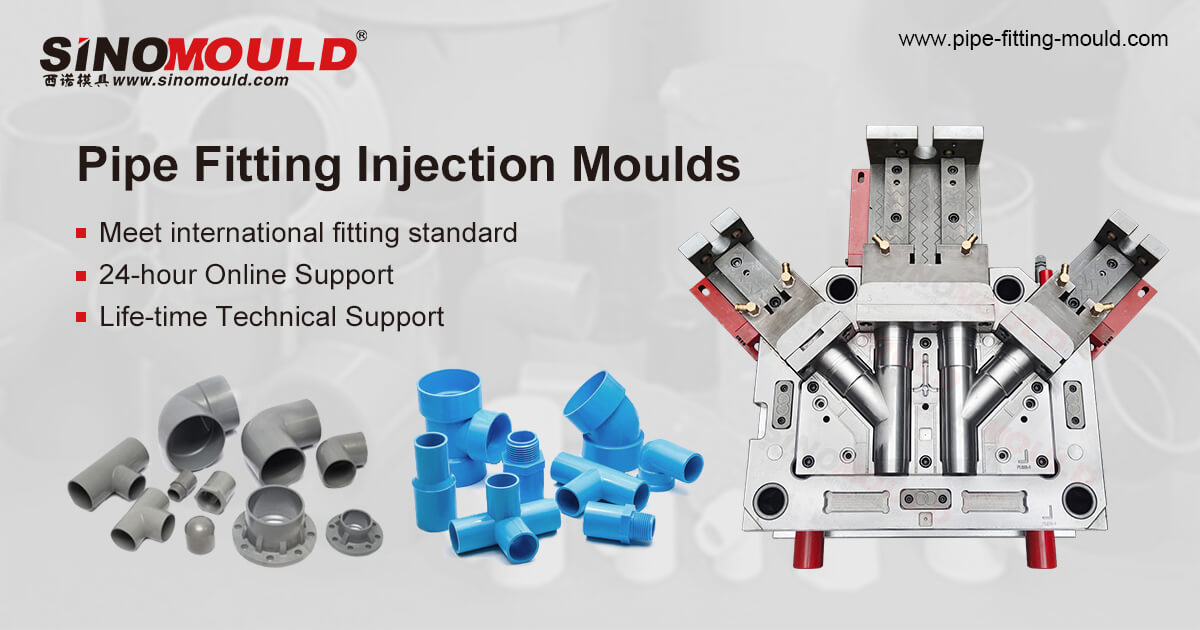

The pipe fitting molds market has begun to grow, and our technical research on this type of mold is constantly improving, in order to allow our molds to meet customer requirements for products during the production process.

Look forward to your inquiry, we will be happy to answer you and provide thoughtful service.